cnc machining service

CNC Machining Services | Precision Manufacturing Solutions

Overview

Our CNC machining services are dedicated to providing high-precision custom parts to customers worldwide. Leveraging advanced equipment, a diverse material selection, and an experienced engineering team, we can meet a full range of needs, from rapid prototyping and small-batch production to large-scale mass production, ensuring high precision, stability, and efficient delivery for every project.

Machinable Materials

We support a wide range of material processing to meet the mechanical performance and functional requirements of various industries:

Metal Materials

Aluminum alloys (6061, 6063, 5052, 6082, 7075), stainless steels (304, 316, 430, 630, 17-4PH), copper, brass, titanium alloys, carbon steel, tool steel

Plastic Materials

POM, ABS, nylon, polycarbonate, PTFE, PEEK, acrylic, HDPE, UHMW

Special Materials

Magnesium alloys, Inconel high-temperature alloys, etc., suitable for demanding applications such as aerospace and medical.

Advanced Equipment

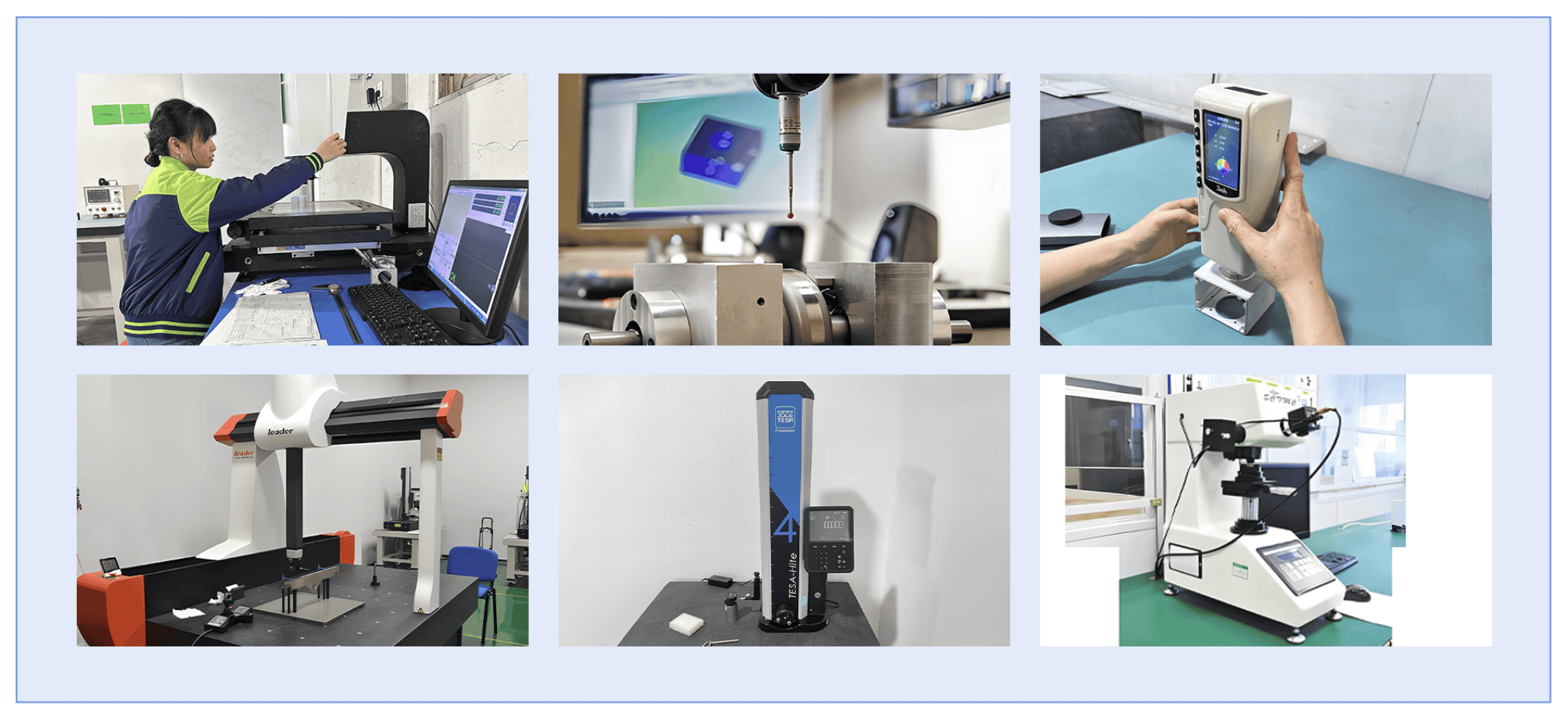

Our factory is equipped with advanced processing and testing equipment to handle complex designs and tight tolerances:

3-axis, 4-axis, and 5-axis CNC machining centers

CNC turning and milling CNC milling machines

CNC machining centers, Swiss-type lathes, suitable for machining small precision parts

Coordinate measuring machines (CMMs), height gauges, digital calipers, and other professional inspection tools

Processing Capabilities

We offer full-process CNC machining to meet diverse product design and production needs:

CNC milling

CNC turning

Drilling and tapping

Threading

Five-axis complex surface machining

High-speed prototyping

Small and large-volume production

Surface treatment

A variety of surface treatments enhance product appearance, corrosion resistance, and performance:

Anodizing (clear, black, colored)

Powder coating

Electroplating (zinc, nickel, chrome)

Brushing, polishing

Sandblasting

Heat treatment, case hardening

Customized surface effects to meet special project requirements

Technical Advantages

High-precision tolerances: Accuracy up to ±0.005mm

Flexible Production: Supports single-piece prototypes to high-volume production

Complex Structure Machining: Specializes in manufacturing complex and challenging parts

Wide Material Range: Covers conventional metals, plastics, and specialized high-performance alloys

Fast Delivery: Guaranteed turnaround time even for urgent orders

Quality Assurance

We strictly adhere to the ISO9001:2015 quality management system to ensure consistent product quality:

Raw material incoming inspection

Multiple inspections during processing

100% final inspection of critical dimensions

Complete dimensional inspection reports available

Industries Served

Aerospace

Automotive and Racing

Medical Devices

Electronics and Robotics

Industrial Machinery

Consumer Products

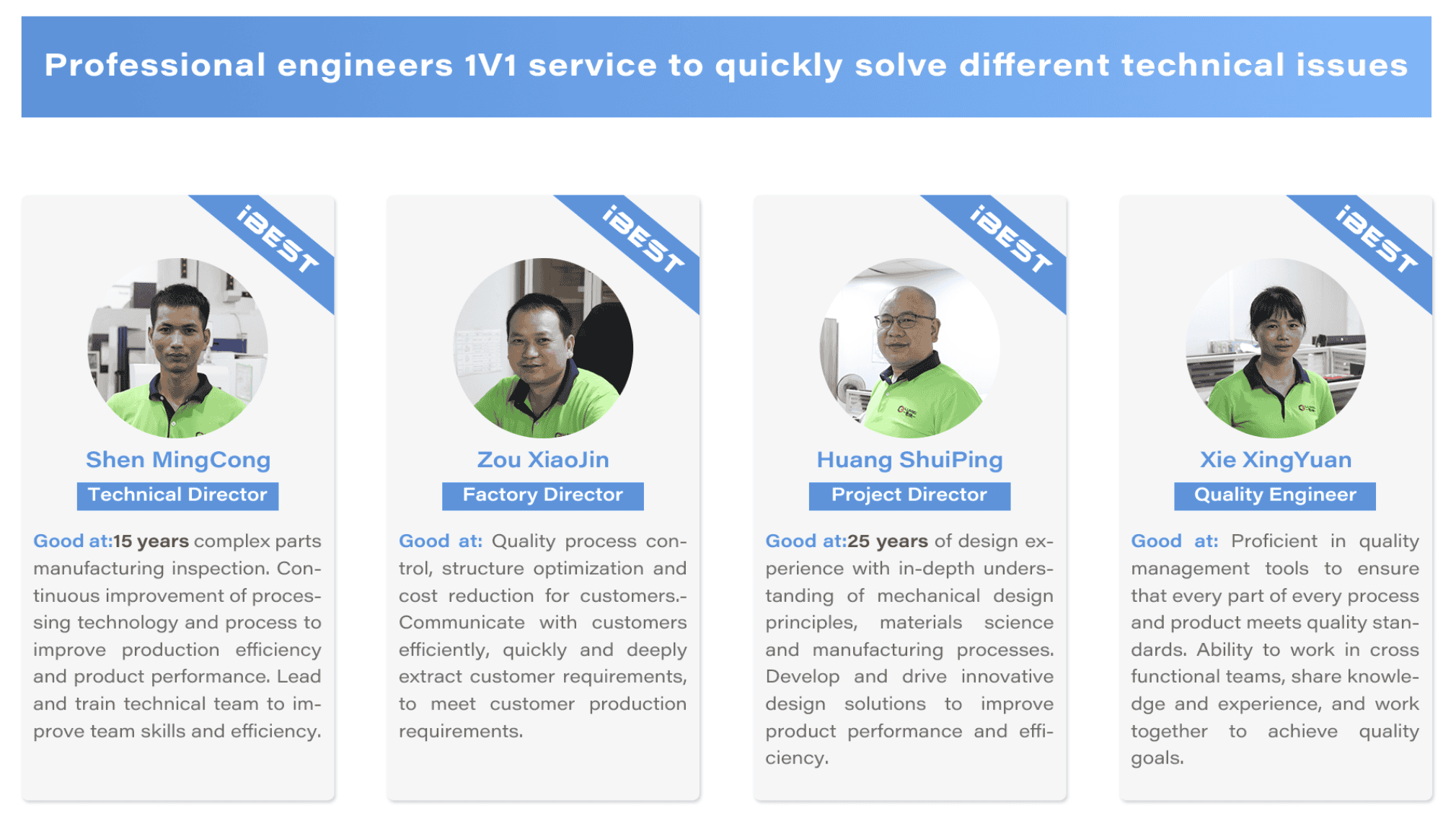

Why Choose Us

Over 10 years of precision machining experience

Professional DFM (Design for Manufacturability) support

Cost-effective solutions that balance quality and cost

Global shipping and on-time delivery

Comprehensive after-sales service fosters long-term partnerships

Service Process

Drawing Submission – Upload CAD drawings or 3D files

Quote and Design Suggestion – Our engineering team will provide a proposal within 24 hours

Prototyping and Verification – Ensure design and functionality meet requirements

Mass Production – Efficient, stable, and traceable

Inspection and Delivery – 100% quality inspection before shipment

Get a quote now

Looking for a reliable CNC machining partner?

Upload your drawings or technical files, and our engineers will provide a free quote within 24 hours.

Injection Molding Services

Injection Molding Services  cnc machining service

cnc machining service  Aluminum Profile Heat Sinks

Aluminum Profile Heat Sinks