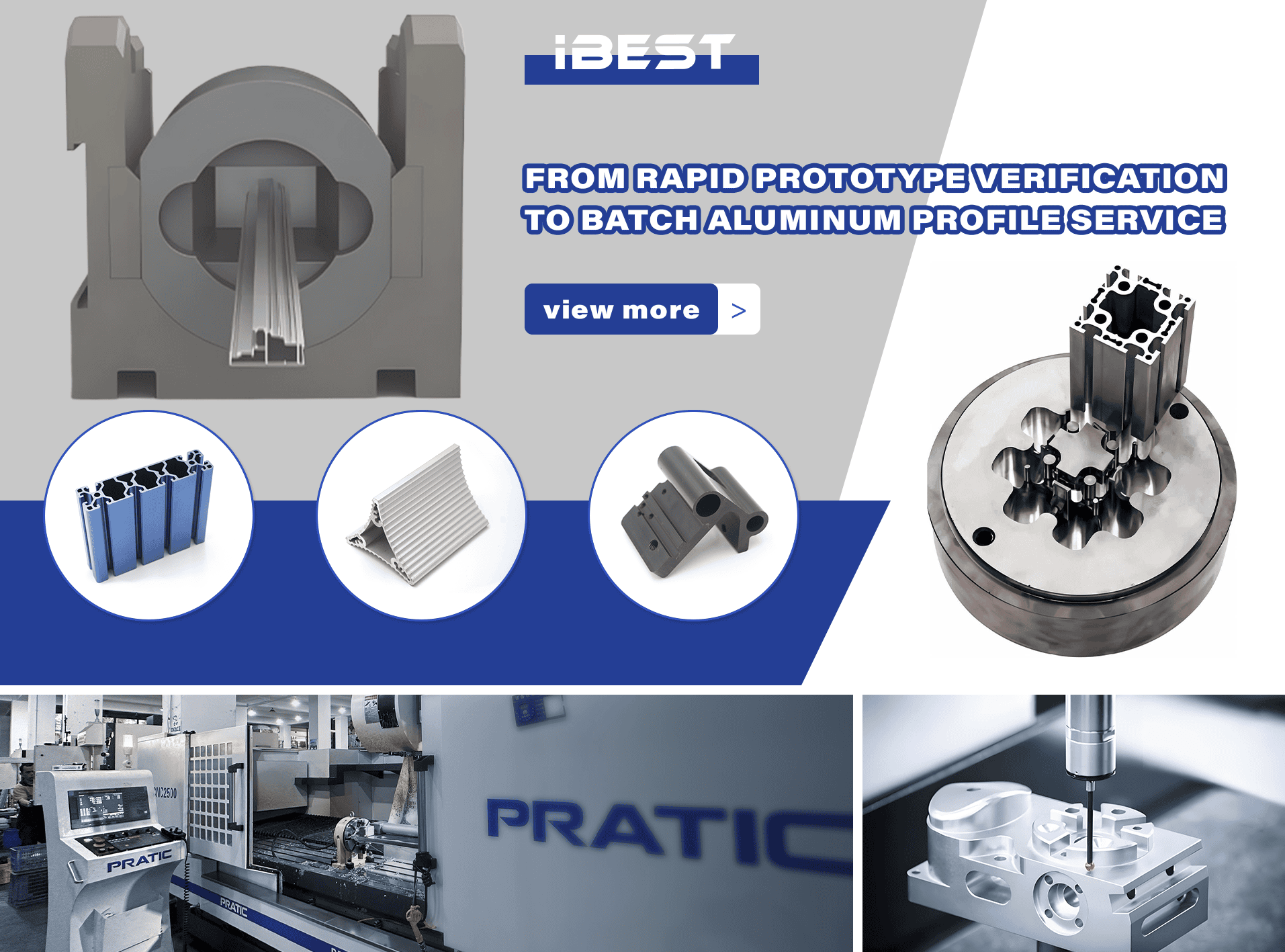

Aluminum Profile Heat Sinks

Aluminum Profile Heat Sinks | Efficient Cooling Solutions

Overview

We specialize in the design and manufacture of aluminum profile heat sinks, providing global customers with high-thermal conductivity, high-strength, and lightweight cooling solutions. Our products are widely used in LED lighting, power supply equipment, communication base stations, inverters, new energy vehicles, industrial control systems, and other fields, helping customers achieve higher heat dissipation efficiency and longer product lifespan.

Machinable Materials

We select high-quality aluminum alloys that meet international standards to ensure excellent thermal conductivity and mechanical strength:

Conventional Aluminum: 6063, 6061, 6005, 6060

High Thermal Conductivity Aluminum: 1070, 1350, 5052 (for high heat dissipation requirements)

Special Alloys: We can customize high-performance aluminum profiles to meet customer needs.

All materials are certified to international environmental standards, including RoHS and REACH.

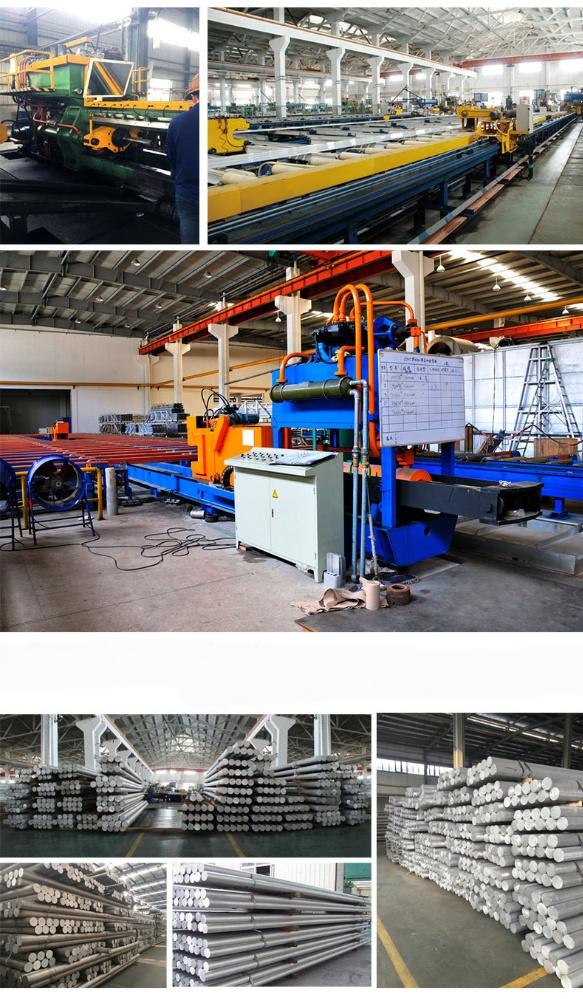

Advanced Equipment

We have a complete production chain, from aluminum bar extrusion to finishing and surface treatment, ensuring consistent quality and manageable delivery times:

Extrusion Line: 500-2000 ton extruders

Further Processing Equipment: CNC milling machines, CNC drilling machines, lathes, punching machines

Assembly and Welding: Riveting, spot welding, brazing, and hot-plugging

Testing Equipment: Coordinate Measuring Machines, Hardness Testers, Thermal Conductivity Testers

Processing Technology

We provide a full-process aluminum extrusion heat sink manufacturing process:

Aluminum bar extrusion: Achieve high-precision profiles

CNC finishing: CNC milling, drilling, tapping, turning Cutting

Welding and Assembly: Heat pipe welding, inserts, spot welding, etc.

High-Precision Cutting: Meet various length and angle requirements

Customized Design: Process according to drawings or assist with design optimization

Surface Treatment

Various surface treatments enhance product performance and appearance:

Anodizing (natural, black, and colored)

Sandblasting

Coating (powder coating, electrophoretic coating)

Chemical Oxidation

Thermal Coating (for special heat dissipation requirements)

Technical Advantages

High Thermal Conductivity: Made of high-quality aluminum alloy, thermal conductivity is significantly improved.

High-Precision Machining: CNC finishing ensures controlled dimensional tolerances. ±0.05mm

Flexible Customization: Supports small-batch prototyping to large-volume production

Structural Optimization: Provides DFM (Design for Manufacturability) recommendations to improve heat dissipation performance

Fast Delivery: Integrated extrusion, processing, and surface treatment services shorten lead times

Quality Assurance

We strictly adhere to the ISO9001:2015 quality management system, and every heat sink undergoes rigorous testing:

Material composition testing to ensure purity

Extruded profile dimensions and flatness testing

100% spot inspection of finished dimensions

Surface treatment corrosion resistance and adhesion testing

Thermal conductivity and strength verification

Applications

Our aluminum profile heat sinks are widely used in various industries:

LED Lighting: Lamp heat sinks, floodlight heat sinks

Power and Energy: Inverters, power module heat sinks

Communications Equipment: Base station and cabinet cooling solutions

New Energy Vehicles: Control system and battery management heat sinks

Industrial Automation: Servo motors, control cabinet heat sinks

Why Choose Us

Over 10 years of experience in aluminum extrusion heat sink production

One-stop capabilities for extrusion, deep processing, and surface treatment

OEM/ODM customization supported

A comprehensive testing system ensures stable and reliable quality

Global shipping, on-time delivery, and efficient service

Service Process

Requirement Communication – Provide drawings or design proposals

Technical Evaluation – Optimize structural and material solutions

Prototype Testing – Verify performance and accuracy

Mass Production – Stable and efficient processing

Inspection and Delivery – Fast shipment after strict quality inspection

Get a Quote Now

Looking for a custom high-performance aluminum extrusion heat sink?

Upload your drawings or technical requirements, and our engineers will provide you with a professional quote within 24 hours.

[Contact Us] – Make cooling solutions more efficient and precise!

Injection Molding Services

Injection Molding Services  cnc machining service

cnc machining service  Aluminum Profile Heat Sinks

Aluminum Profile Heat Sinks