Injection Molding Services

Injection Molding Services | Precision Plastic Part Solutions

Overview

We are a professional injection molding factory dedicated to providing high-quality, precision plastic parts to customers worldwide. Leveraging advanced injection molding equipment, extensive material expertise, and a dedicated engineering team, we can meet diverse needs, from rapid prototyping to small batch production and large-scale mass production. Our products are widely used in a variety of industries, including automotive, electronics, medical, consumer goods, and industrial parts.

Processable Materials

We support the processing of a wide range of engineering plastics and general-purpose plastics to meet diverse functional and performance requirements:

Common General-Purpose Plastics: PP, PE, ABS, PS, PVC, HIPS

Engineering Plastics: PC, PA (Nylon), POM, PMMA (Acrylic), PET, PBT

High-Performance Plastics: PEEK, PEI, LCP, PTFE, TPU

Additive-Modified Materials: Glass Fiber Reinforced, Flame Retardant, UV Resistant, Antistatic, Antibacterial, and Other Materials

Advanced Equipment

Our factory is equipped with fully automated production equipment, ensuring efficient and stable production capacity:

Precision Injection Molding Machines (Clamping Forces from 50T to 800T)

Hot Runner Systems Compatible with Cold Runner Molds

Multi-cavity molds and two-color injection molding machines

Fully automatic robotic arms and assembly lines

Mold temperature control systems and drying equipment

Processing technology

We provide full-process injection molding solutions:

General injection molding

Precision injection molding

Two-color injection molding/multi-component injection molding

Insert injection molding

Gas-assisted injection molding

Micro injection molding

Rapid prototyping and low-volume production

Surface treatment

To enhance product appearance and performance, we offer a variety of surface treatments and post-processing technologies:

Silk screen printing, pad printing, painting

Laser engraving

Electroplating, vacuum plating

Polishing, texturing

Ultrasonic welding, hot melt welding

Customized surface effects

Technical advantages

High precision: Dimensional tolerances can be controlled within ±0.02mm

Diverse Production Capabilities: Supporting everything from single-piece prototypes to million-level production runs

Complex Structure Support: Specializing in multi-cavity, complex structure, and high-precision mold parts

Material Matching Service: Recommending the optimal plastic material based on product function

Fast Delivery: Reduce mold manufacturing and mass production cycles by over 30%

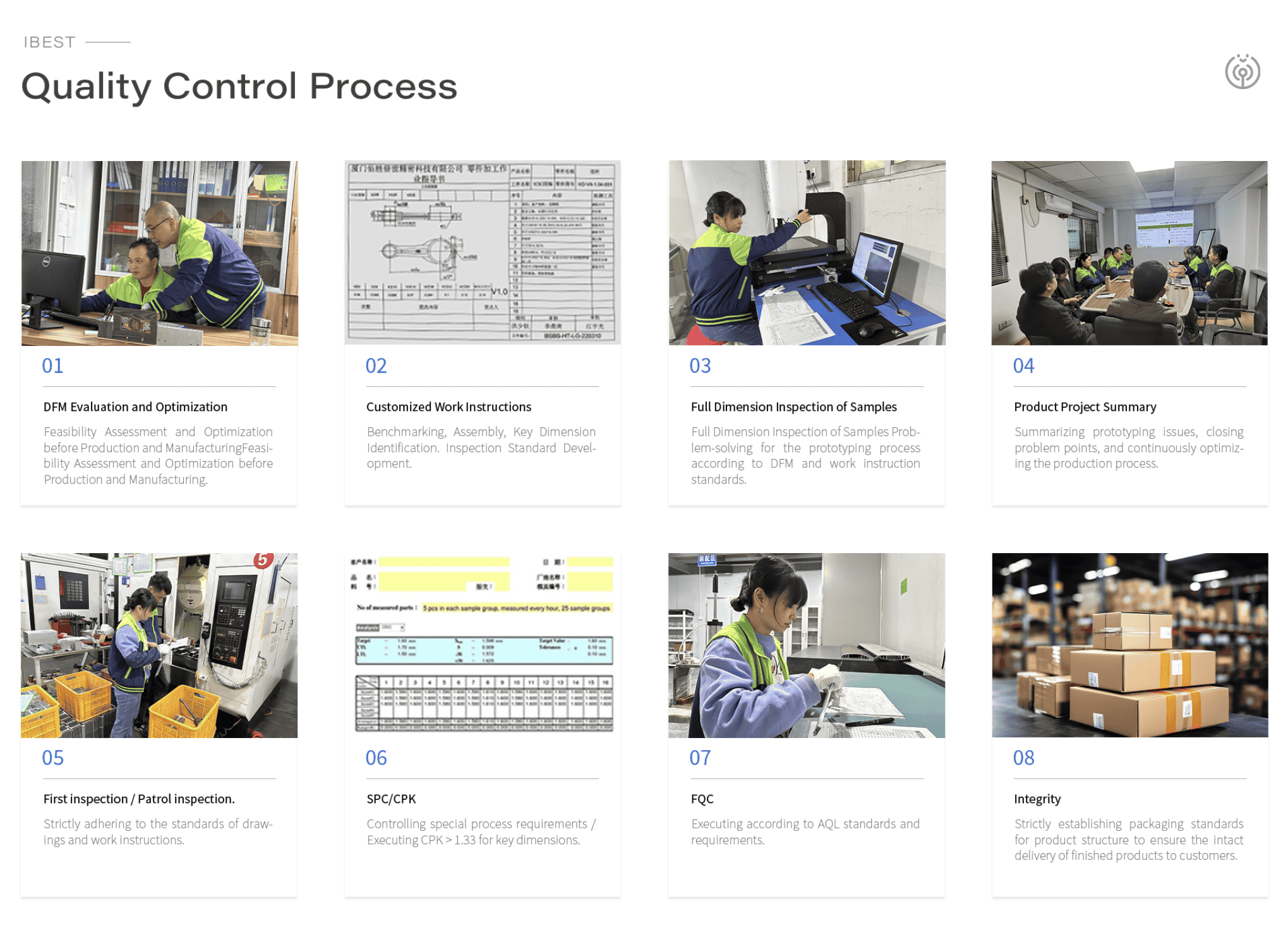

Quality Assurance

We strictly adhere to the ISO9001:2015 quality management system to ensure every product meets customer standards:

Raw Material Inspection: Ensures traceability of material sources

Process Control: Real-time monitoring of injection molding parameters ensures product consistency

Full or Spot Inspection: Meet varying precision and batch requirements

Quality Reports: Provide complete test reports and factory certificates

Industries Served

Our injection molding products are widely used in:

Automotive: Interior components, functional parts, precision parts

Consumer electronics: Housings, connectors, structural components

Medical devices: Housings, handles, precision medical components

Industrial parts: Gears, valve bodies, seals

Home appliances and daily necessities: Housings, functional parts, custom products

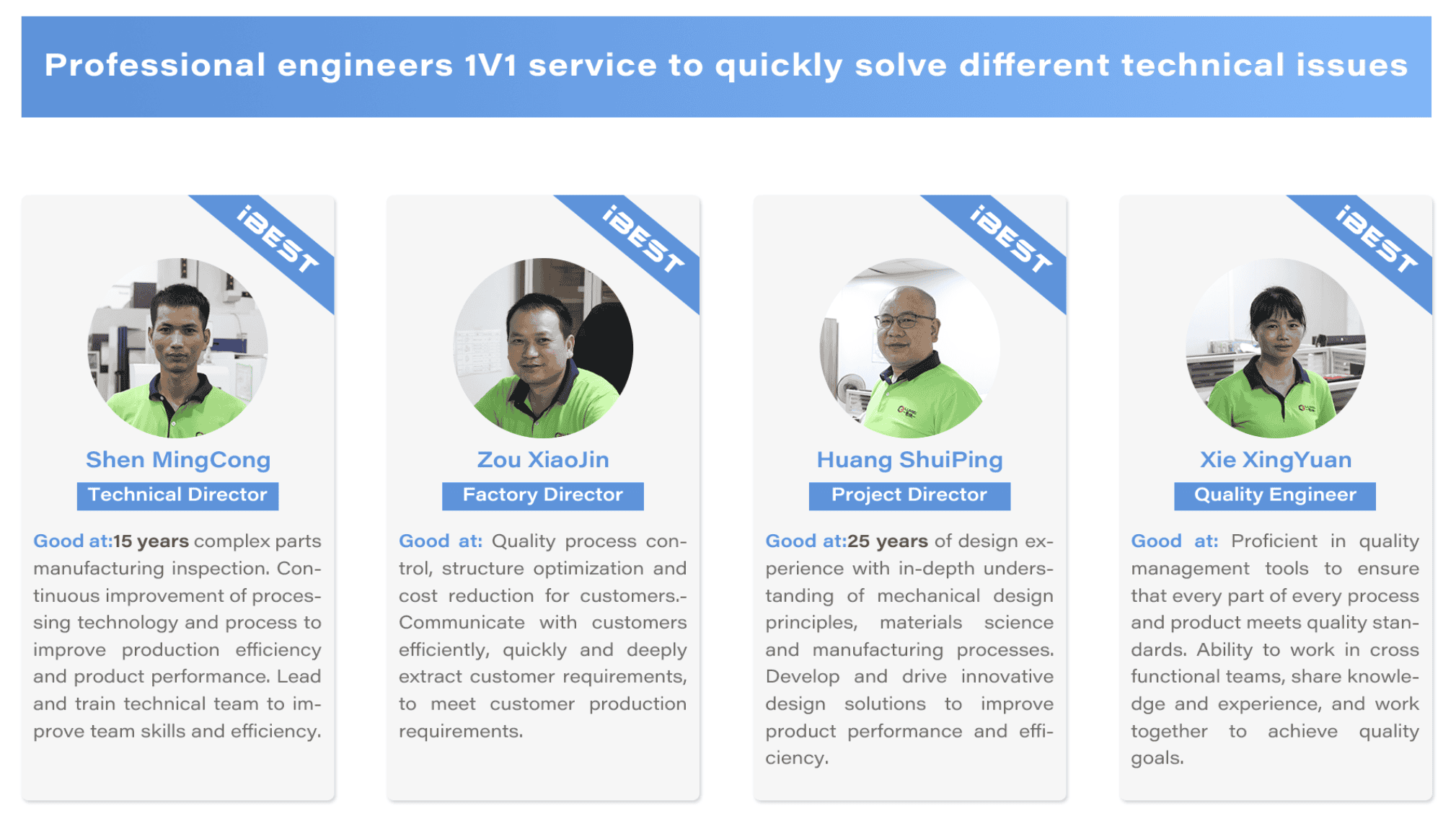

Why Choose Us

Over 10 years of injection molding experience, with extensive technical expertise

Our in-house mold design and manufacturing team provides one-stop service from design to mass production

Flexible production models accommodate high-volume demands

Globally recognized, exporting to multiple markets including Europe, America, and Southeast Asia

Comprehensive after-sales support fosters long-term partnerships

Service Process

Customer Service – Submit drawings or samples

Solution evaluation – Material and process recommendations

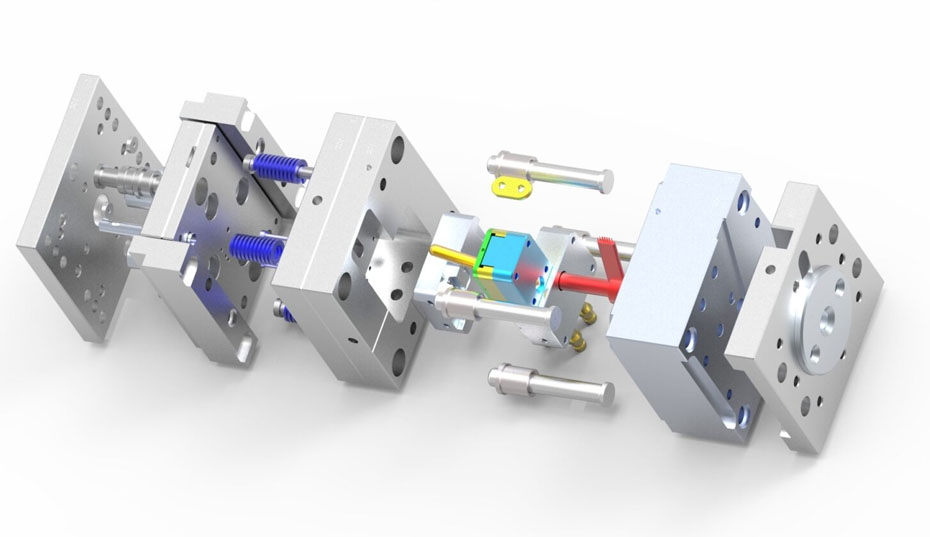

Mold manufacturing – Fast delivery of high-precision molds

Mold trial and proofing – Verify dimensions and performance

Mass production – Stable and efficient production processes

Inspection and delivery – Fast shipment after rigorous quality inspection

Get a quote now

If you're looking for a reliable injection molding partner, upload your drawings or samples and we'll provide a professional quote within 24 hours.

[Contact Us] – Rapidly transform your ideas into mass production!

Injection Molding Services

Injection Molding Services  cnc machining service

cnc machining service  Aluminum Profile Heat Sinks

Aluminum Profile Heat Sinks